“D&P” Super Steel: a Super-Strong and Ductile Multi-phase Steel

- Field

- Advanced Materials

- Patent

- IP00654

Key Problem and Market Opportunity

- Steel is the most widely used metallic materials which can be produced efficiently than any other metallic materials

- Automotive, aerospace and defense applications require steel with ultra-high strength

- However, increasing strength often leads to the decrease in ductility, which is known as the strength-ductility trade-off

- Developing a strong, high tensile and yet highly ductile steel has long been the quest for many researchers

- The world’s AHSS market is estimated to worth US$28 billion in 2017

Key Advantages of the Technology

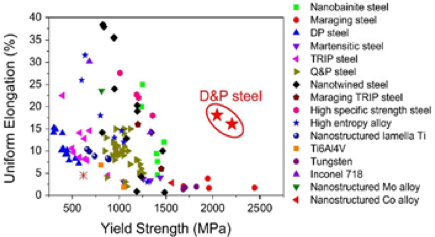

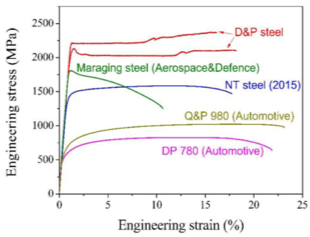

- Our “D&P” Super Steel is a strong, highly tensile and yet highly ductile steel

- With a simple 4-step low-cost fabrication method which involves warm rolling, annealing, cold rolling and tempering, it is a breakthrough in the steel industry

- It is the 3rd generation AHSS (Advanced High Strength Steel)

| Conventional Steel | “D&P” Super Steel | |

|---|---|---|

| Strength and Ductility | ✗ Limited by “strength-ductility” tradeoff | ✓ Overcome “strength-ductility” tradeoff |

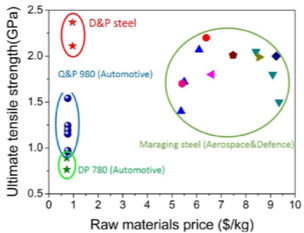

| Raw Material Costs | ✗ High | ✓ Low (~20% of the maraging steel) |

| Weight | ✗ Heavy | ✓ Light |

| Fabrication Process | ✗ Complex | ✓ Simple |

| Manufacturing Scalability | ✗ Low | ✓ High |

Potential Product and Services

- Advanced high strength and light weight steel for the Automotive Industry

- Advanced high strength steel for the Aerospace Industry

- Advanced high strength steel for Construction Industry like the galvanized steel wires used by suspension bridges

Development Status and IP Strength

- PCT Application No. PCT/CN2016/096509

- Device prototype is available in laboratory scale